Powder feeding and measuring system

- Time of issue:2020-06-29

Powder feeding and measuring system

(Summary description)One hundred thousand clean electric hoist, wireless remote control operation, no friction between metals;

- Time of issue:2020-06-29

- Views:

Information

Ton bag feeder:

Clean-level electric lifting mechanism;

Suitable for large bags or small bags of materials, convenient and quick operation;

It has the functions of automatic sieving and iron removal of materials;

The interior is equipped with dust filtering and automatic recovery devices, the silo is equipped with an air circulation system, and the air volume can be adjusted;

Grid-type permanent magnet iron remover is optional; 10000-12000GS;

It has the function of preventing material clogging, the function of locking the bag opening, and the function of opening and closing the automatic feed opening.

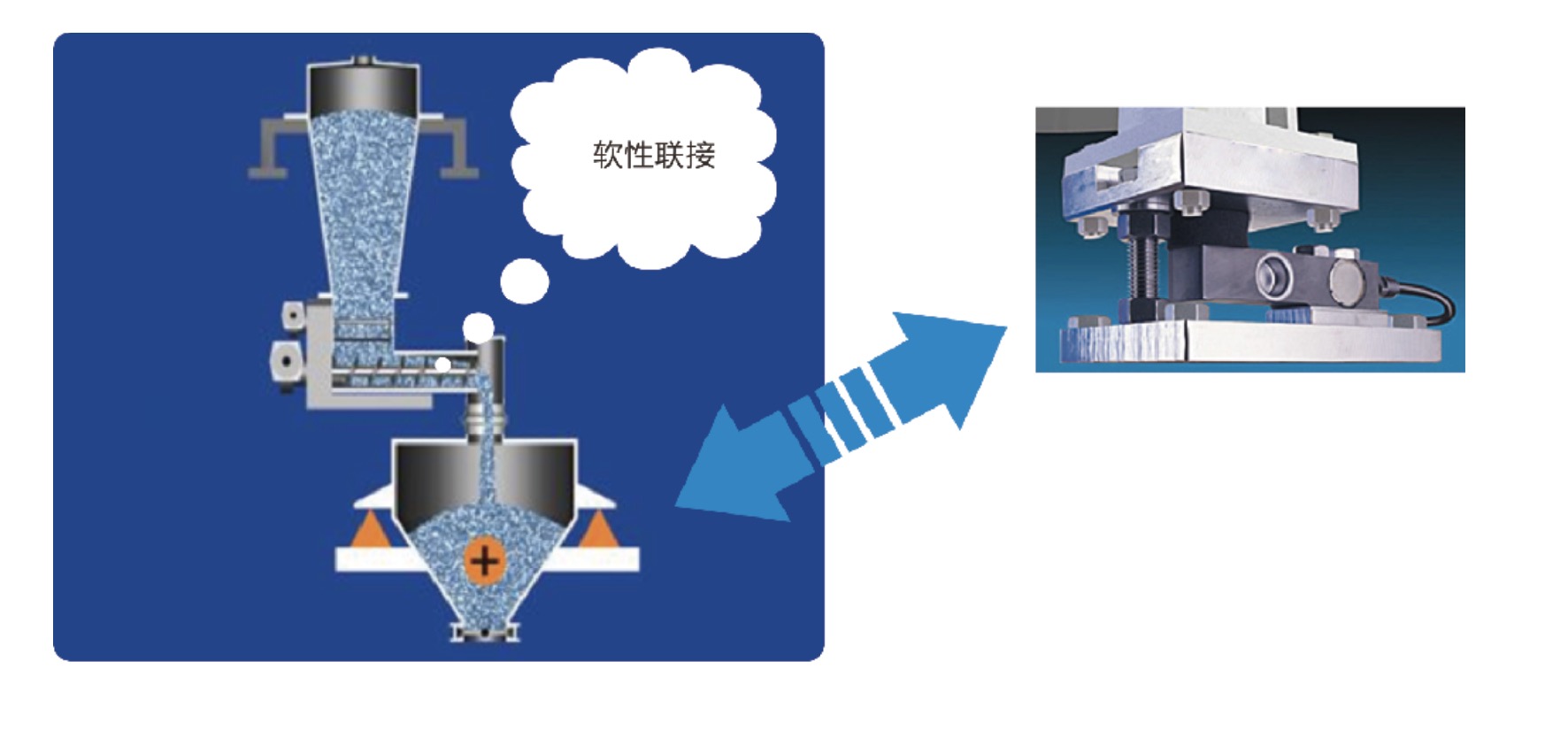

Powder quantitative measurement system :

Using the principle of incremental and loss-in-weight measurement,

Measure the material twice and compare the data to check whether there is a measurement error.

used for continuous ingredients in industrial production process,

The weighing device on the equipment measures the materials in the hopper on the equipment with high precision,

At the same time, the spiral feeding device controls the material to be sent to the measuring tank at a constant flow rate through the servo motor.

The material in the storage tank will decrease continuously, and the weight signal obtained by the load cell will change accordingly.

The controller adjusts the speed of the motor in real time through the signal change of the sensor,

Therefore, a higher measurement accuracy is achieved.

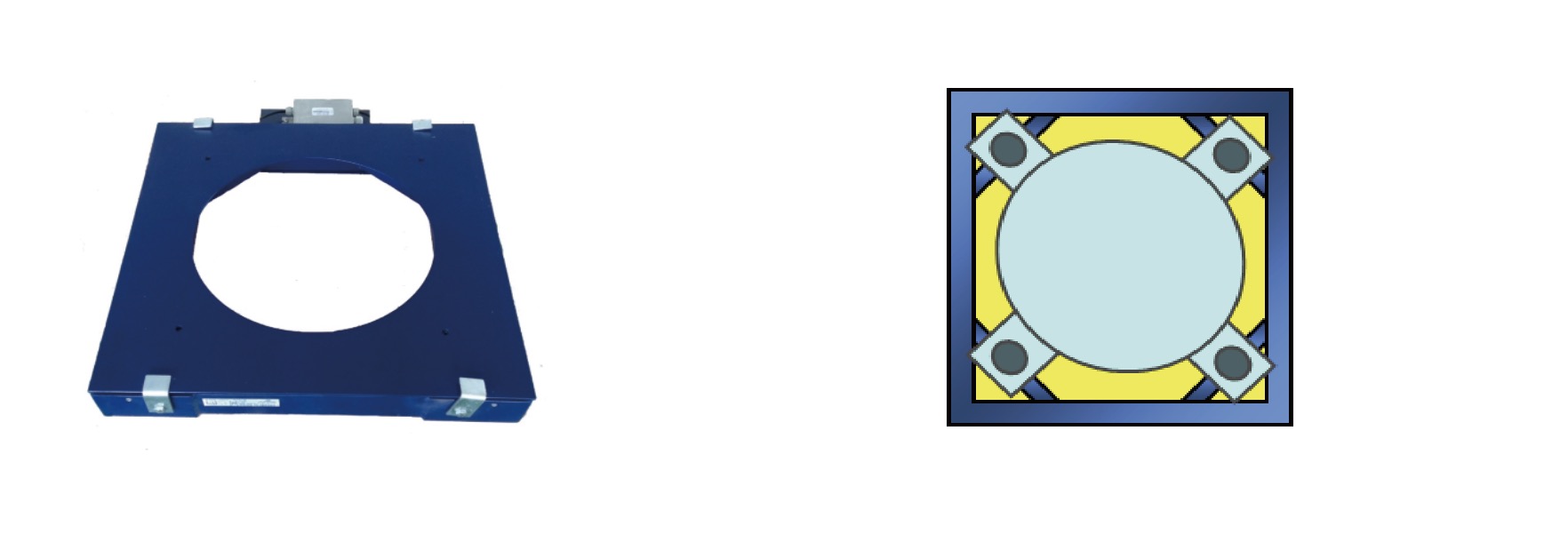

Measuring platform scale:< /strong>

Platform structure design, composed of sensors, top plate, bottom plate, connectors, etc.,

Place the measuring tank on the platform scale, and the four groups of sensors are distributed in the four corners of the platform,

Make each group of sensors receive even force.

The platform structure solves the weighing error caused by improper installation and the impact on the service life of the sensor.

Ensure the accuracy and long-term stability of the sensor.

Excessive horizontal shearing and lifting forces may tilt or rotate the tank, causing the tank to shift,

Therefore, a non-vertical load force is generated, and the platform scale can bear a certain force.

Due to the small particle size of the powder, poor flowability and easy dusting,

Moreover, it is affected by moisture temperature, pressure, and inflation state,

Brings great difficulties to measurement and control.

After years of development and practical application, the company,

A number of products have been studied to complete high-precision dynamic measurement of different powdery materials.

Dynamic measurement of powder materials is mainly done through the feeder to complete the non-material quantitative feeding,

The controller monitors the feedback signal of each sensor in real time,

Precise measurement is accomplished by adjusting the feeding speed and feeding amount of the feeder.

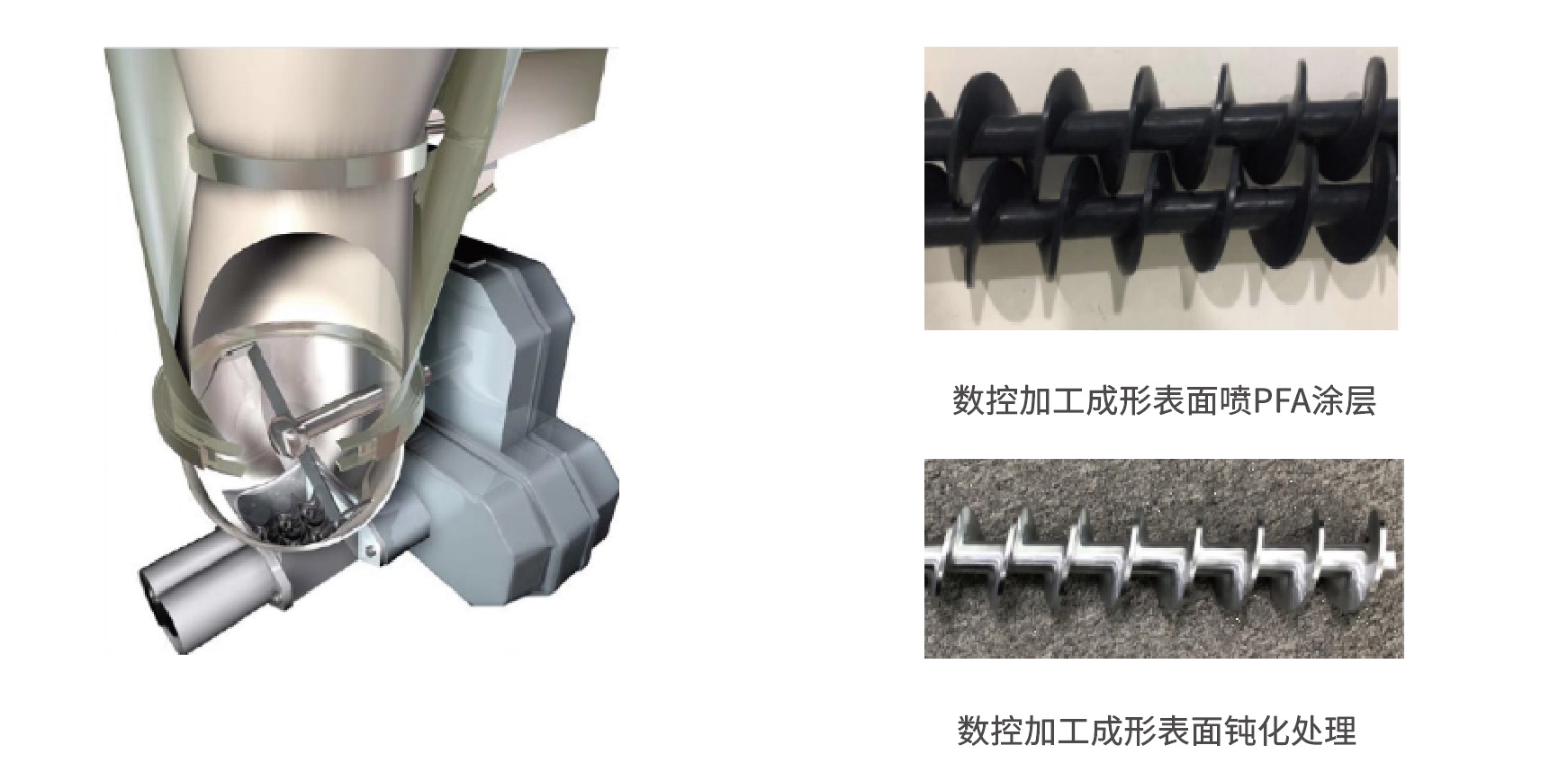

Twin screw feeder :

Dynamic metering of powder materials is mainly conveyed by the rotation of the screw feeder blades,

The controller monitors the feedback signal of each sensor in real time,

Precise measurement is accomplished by adjusting the conveying speed and conveying volume of the feeder.

The automatic arch breaker can effectively ensure that the powder material is not blocked.

Previous:

PD Mixer

Previous:

PD Mixer

Copyright © 2020 Shenzhen Jiewei Industrial Equipment Co., Ltd.All rights reserved